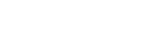

Each trolley in the system is driven independently.

The structure is composed of tracks, side track for horizontal movement, turntables, elevator sections, etc., forming a 3D conveying network.

A variety of control methods can be adopted, such as centralized control, decentralized control or distributed control, and the trolley performs fully automatic operation according to the set program.

Random material supply system, the station can apply for a trolley at random, and write the characteristic address code of the trolley station randomly through the trolley, and directly reach the car station to supply materials.

Sorting and distribution system. According to the characteristic address codes carried by different types of goods carried by the cargo trolley, an address reading station is set up on the ground, which can realize automatic sorting and distribution operations, etc.

Parameter

Parameter| MODEL | LENGTH(m) | POWER(kw) | ORBIT(kg) | GEAR DIAMETER(Φ)mm | OUTPUT GEAR | LOAD-BEARING(T) | BEAM SPAN(m) |

| DGTC-0.75-130 | 0.75 | 0.4 | 9 | 130 | M3 | 1 | 6 |

| DGTC-1.2-150 | 1.2 | 0.4 | 9 | 150 | M3 | 1.5 | 6 |

| DGTC-1.5-150 | 1.5 | 0.4 | 9 | 150 | M3 | 2 | 8 |

| DGTC-1.8-150 | 1.8 | 0.4 | 9 | 150 | M3 | 2 | 8 |

| DGTC-1.2-180 | 1.2 | 0.4 | 12 | 180 | M3 | 2 | 8 |

| DGTC-1.8-180 | 1.8 | 0.4 | 12 | 180 | M3 | 3 | 8 |

| DGTC-2.0-180 | 2 | 0.4 | 12 | 180 | M3 | 3 | 10 |

| DGTC-2.2-180 | 2.2 | 0.4 | 12 | 180 | M3 | 3 | 12 |

| DGTC-2.0-200 | 2 | 0.4 | 12 | 200 | M4 | 5 | 12 |

| DGTC-2.2-220 | 2.2 | 0.75 | 12 | 220 | M4 | 5 | 12 |

| DGTC-2.5-220 | 2.5 | 0.75 | 12 | 220 | M4 | 7.5 | 15 |

| DGTC-2.2-250 | 2.2 | 0.75 | 15 | 250 | M4 | 7.5 | 12 |

| DGTC-2.5-250 | 2.5 | 0.75 | 15 | 250 | M4 | 7.5 | 15 |

| DGTC-3.0-250 | 3.5 | 0.75 | 15 | 250 | M4 | 10 | 22 |

| DGTC-2.5-280 | 2.5 | 0.75 | 22 | 280 | M5 | 10 | 12 |

| DGTC-3.0-280 | 3 | 0.75 | 22 | 280 | M5 | 10 | 15 |

| DGTC-3.5-280 | 3.5 | 0.75 | 22 | 280 | M5 | 15 | 15 |

| DGTC-2.5-300 | 2.5 | 2.2-1.5 | 30 | 300 | M5 | 15 | 12 |

| DGTC-3.0-300 | 3 | 2.2-1.5 | 30 | 300 | M5 | 15 | 15 |

| DGTC-3.5-300 | 3.5 | 2.2-1.5 | 30 | 300 | M5 | 15 | 15 |

Advantages

Advantages

Hebei Huaige Lifting Machinery Group Co., Ltd. was founded in 1980 and is a light and small lifting machinery manufacturing enterprise rooted in the land of Yanzhao. After 40 years of ups and downs and 20 years of rapid development, it has stood out.

Huaige Group is committed to providing supporting products for lifting machinery equipment, serving industries such as industrial lifting, stage lifting, energy wind power, and logistics assembly. It also provides intelligent solutions and mature supporting products, deeply cultivating the global market.

Huaige Group has successively obtained the national industrial product production license for manual hoists, obtained the export product quality license, and successfully obtained multiple honors such as ISO9001 quality management system certification and China's self operated import and export rights production enterprise.

Tomorrow's Huaige will be built into a development enterprise with modern equipment, scientific management, stable products, and networked operations

Tomorrow's Huaige will be built into a development enterprise with modern equipment, scientific management, stable products, and networked operations