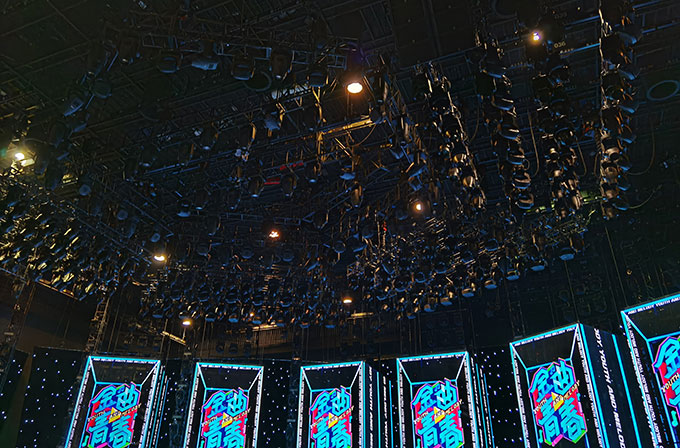

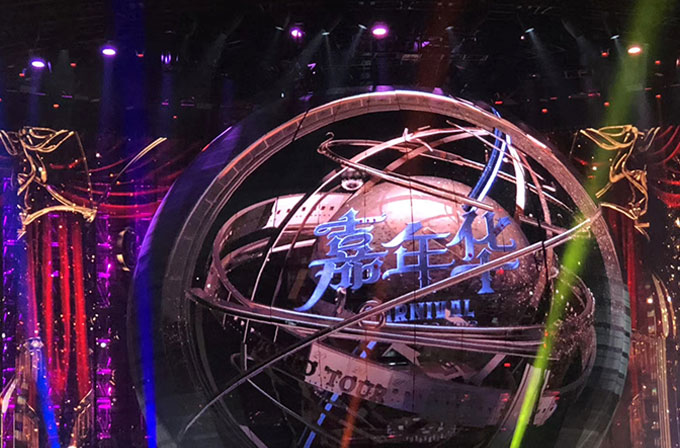

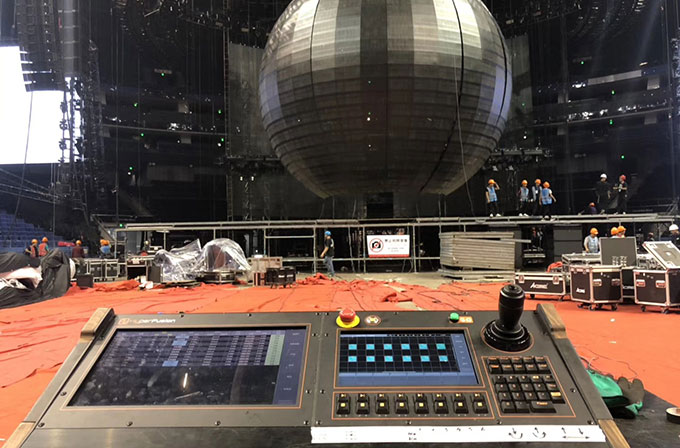

The hoisting operations of stage equipment have extremely high requirements for the safety and durability of the tools. The HM-B hand chain hoist block provides reliable guarantees for stage operations through multiple design optimizations.

HM-B hand chain hoist

This chain block is equipped with a double-pawl automatic braking device. When there are changes in the load or the hand chain is accidentally released, the double pawls can quickly engage to achieve braking, reducing the potential risk of the suspended load falling. Its friction disc is made of special materials. After multiple tests and improvements, it has excellent wear-resistant properties. Even after long-term use, it can still maintain stable frictional performance, ensuring the smoothness of the lifting and lowering operations. The chain guide wheel adopts a unique design, which can precisely regulate the running path of the chain, reducing the friction and wear between components, thus extending the overall service life of the equipment. The large disc, gears, and long and short shafts have undergone heat treatment processes, effectively improving their strength and enabling them to withstand greater load pressure. The hooks and chains have undergone quenching and tempering treatments, enhancing the toughness and hardness of the structure. The upper and lower hooks have been forged and are equipped with safety clips, further improving the safety performance. In addition, the surface of the chain block is powder-sprayed, and the chain is galvanized, effectively enhancing the equipment's ability to resist environmental factors such as moisture and corrosion, and meeting the usage requirements of various stage scenarios.