Horizontally opposed dual independent electromagnetic brakes

The working principle of the horizontal opposition double independent brake electric crane (horizontal opposition double

brake system): based on the design of two electromagnetic brakes with opposing layout, that is, one electromagnetic brake

is on the front of the electric crane, the other electromagnetic brake is on the back of the electric crane, and the two electromagnetic

brakes are installed on the center line of the whole machine.

The two electromagnetic brakes can cancel each other out the force generated by the crane stop when the electric hoist stops,

reducing vibration and noise. The two electromagnetic brakes work completely independently,The response is faster and smoother,

increasing the safety of braking.

Integral high-precision gear rotation device

Spiral helical tooth design can reduce long-term wear, hard tooth surface machining, gear grinding treatment, gear accuracy

grade 6, complete oil valley lubrication, with automatic temperature adjustment function, when frequently used, the temperature

in the gear mechanism can be adjusted, so that the operation is smoother and the operation is quieter.

The one-piece driveshaft design allows for smoother running, lower noise and longer durability.

Friction clutch

Built-in mechanical overload safety clutch, using imported clutch friction plate, when the load weight exceeds the rated load,

the overload prevention device makes the motor idle, to prevent overload and overload damage to the hoist body and chain.

Chain guide device

The unique 45 degree side chain guide device can ensure the smooth operation of the chain and prevent chain jamming.

Lifting sprockets

Made of special alloy steel, double-sided bearings, stable and quiet operation, effectively ensuring the smooth lifting of the

chain. The five-chain nest design lifting sprocket increases the bond between the chain and the gear, reduces vibration and

chain wear, and ensures a smoother lifting process.

Aluminum alloy high-efficiency motor

The motor adopts aluminum alloy stretch shell, unique heat dissipation function, suitable for high-frequency operation,

protection level IP65, insulation grade F.

High-strength aluminum alloy gearbox

The gearbox is made of high-strength aluminum alloy die-casting, which is lightweight, strong, higher strength and good

corrosion resistance.

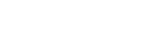

Forged alloy steel hook

The hook is forged from alloy steel, equipped with an anti-decoupling device, the hook can rotate 360 degrees,

and the safety factor is high.

The unique design of the electrophoretic black lifting chain can effectively prevent corrosion.

Parameter

Parameter| Model | CAPACITY(kg) | VOLTAGE(V/3P) | LIFTING HEIGHT(m) | CHAIN FALL NO. | LIFTING SPEED(m/min) | POWER(kw) | LOAD CHAIN DIA(mm) | CHAIN NET WEIGHT(kg) | G.W(kg/m) |

| D11 | 1000 | 220-415 | ≥10 | 1 | 4 | 1.0 | 7.1*21 | 38 | 1.1 |

Advantages

Advantages

Hebei Huaige Lifting Machinery Group Co., Ltd. was founded in 1980 and is a light and small lifting machinery manufacturing enterprise rooted in the land of Yanzhao. After 40 years of ups and downs and 20 years of rapid development, it has stood out.

Huaige Group is committed to providing supporting products for lifting machinery equipment, serving industries such as industrial lifting, stage lifting, energy wind power, and logistics assembly. It also provides intelligent solutions and mature supporting products, deeply cultivating the global market.

Huaige Group has successively obtained the national industrial product production license for manual hoists, obtained the export product quality license, and successfully obtained multiple honors such as ISO9001 quality management system certification and China's self operated import and export rights production enterprise.

Tomorrow's Huaige will be built into a development enterprise with modern equipment, scientific management, stable products, and networked operations

Tomorrow's Huaige will be built into a development enterprise with modern equipment, scientific management, stable products, and networked operations