Product quality is the lifeblood of an enterprise, and high-quality materials are the cornerstone

of ensuring quality, which can determine the strength and durability of the product;

Can provide a stable user experience; Ensure safety and reliability. Therefore,

the manufacturing of the electric hoist for the Huaige stage starts with material

selection, selecting high-quality raw materials such as steel, stainless steel,

aluminum alloy, etc. to be applied to the product body, especially the outer shell,

as well as load-bearing components such as hooks, steel wire ropes,

chains, etc., to ensure that the product can play its due performance.

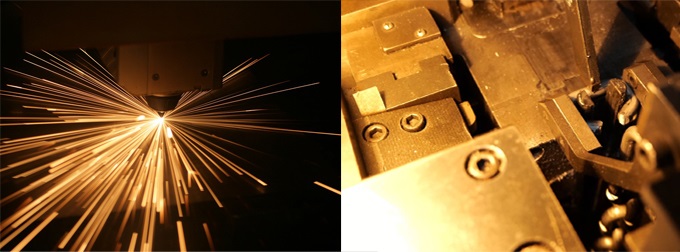

After selecting the materials, the next step is the precision forging process.

Huaige introduces advanced forging equipment to ensure accuracy and precision,

with a refined process flow that pursues in every detail, and professional and

skilled technical workers to control it.Through high-temperature forging, raw materials

are processed into the desired shape and size. In this process, each step needs to

be strictly controlled to ensure that the finished product can meet the needs of the market.

Precision forging can effectively improve the strength of products while maintaining

accurate dimensions, making their appearance more beautiful and streamlined.

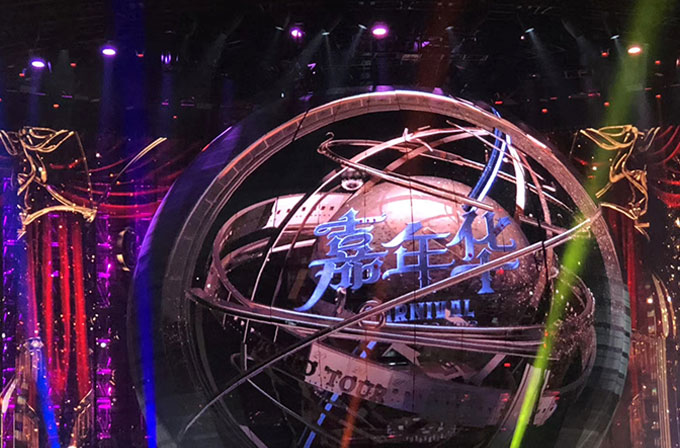

This may not be intuitive enough, so let's use the Huaige HGA8+stage electric

hoist to provide a detailed introduction. The Huaige HGA8+stage electric hoist

adopts an aluminum alloy stretched shell, with unique heat dissipation function

to adapt to high-frequency operations,Protection level IP55; The gearbox is formed

by high-strength aluminum alloy die-casting, which is lightweight, sturdy,

with higher strength and good corrosion resistance;

The hook is forged with alloy steel and equipped with an anti unhooking device,

which can rotate 360 degrees; The lifting sprocket is made of special alloy steel,

and the five chain socket design adopts double-sided bearings, ensuring smooth

and quiet operation. The strict selection of manufacturing materials not only

ensures the high quality and durability of various components of the electric hoist

on the pigeon stage, but also achieves more performance bonuses based on this.

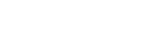

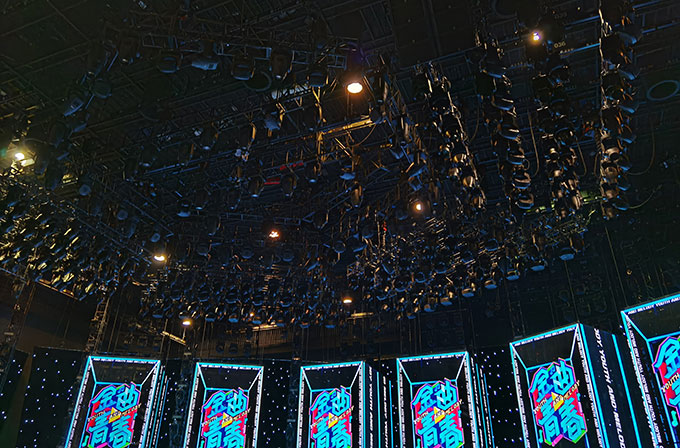

In short, the manufacturing of electric hoists for the Huaige stage cannot be separated

from attention to detail, patience, and craftsmanship. Every stage of pigeon breeding

is highly valued. Only in this way can we not disappoint the trust of our customers and

provide stable and reliable equipment support for stage performances.